Design

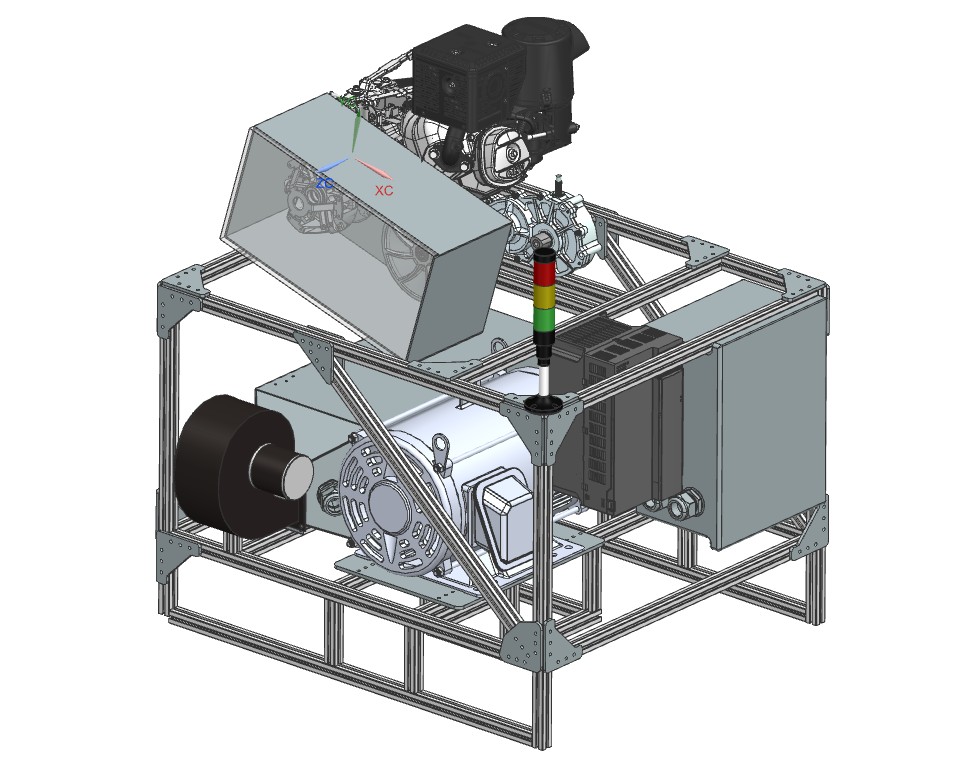

Our car uses a custom CVT, which requires extensive testing and validation to reach optimal performance. In order to accurately mimic the effects of the torque loads the CVT sees, we are using a 20hp motor, which is controlled with a VFD and PLC. In order to dissipate the energy of the motor (approximated to be 20kW), 12 heating elements are being used, and are cooled with a squirrel cage blower. We decided to use aluminum extrusion for the frame to make changing/ updating the design more flexible. The structure is supported with steel brackets to improve its rigidity and fatigue life.

Manufacturing

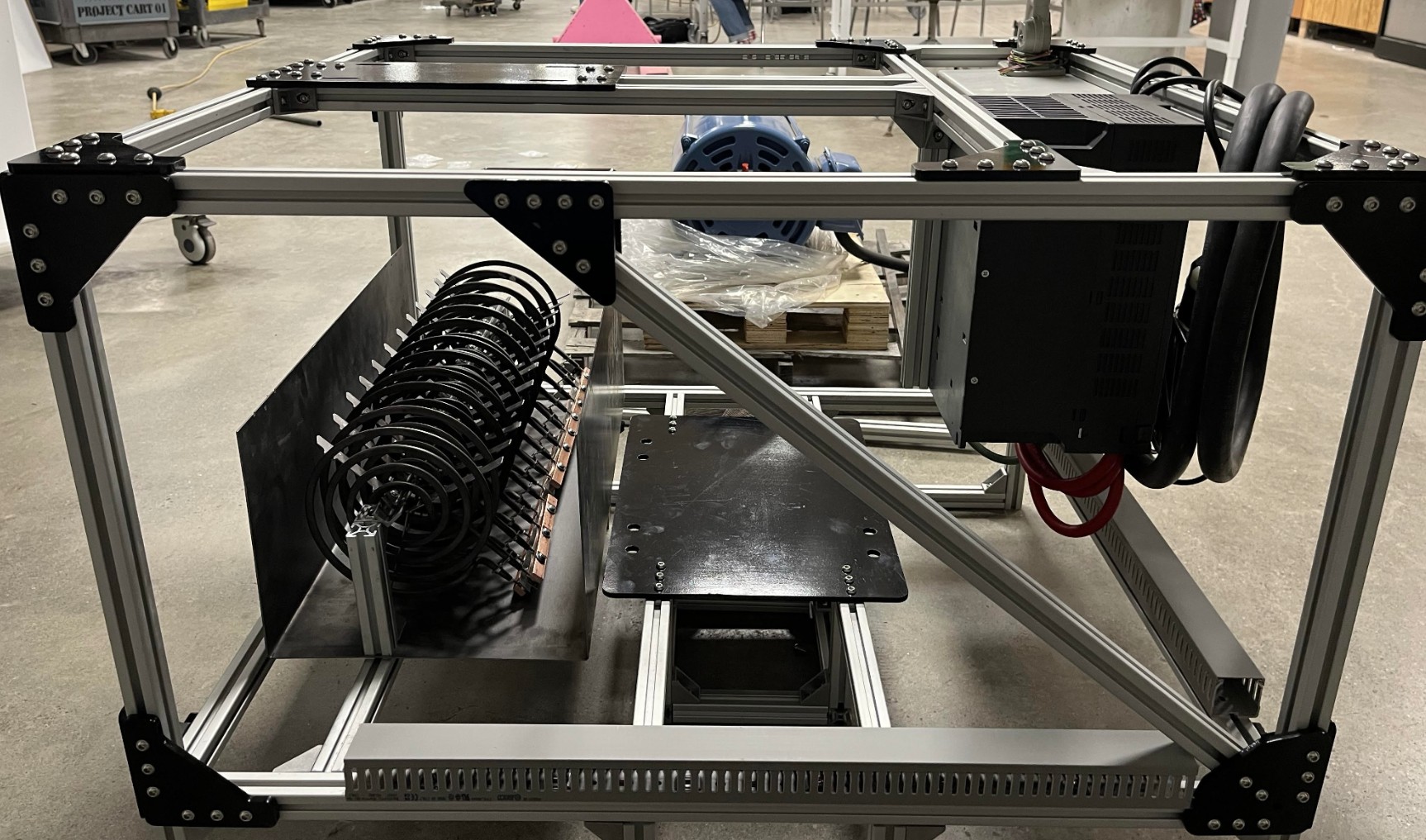

This is the partially assembled form of the dyno. The steel brackets and fixture plates were waterjet out of quarter inch steel, and powder coated to prevent rusting. The aluminun extrusion was cut to length on our vertical bandsaw. The PLC (and more) is housed in the beige electronics box.