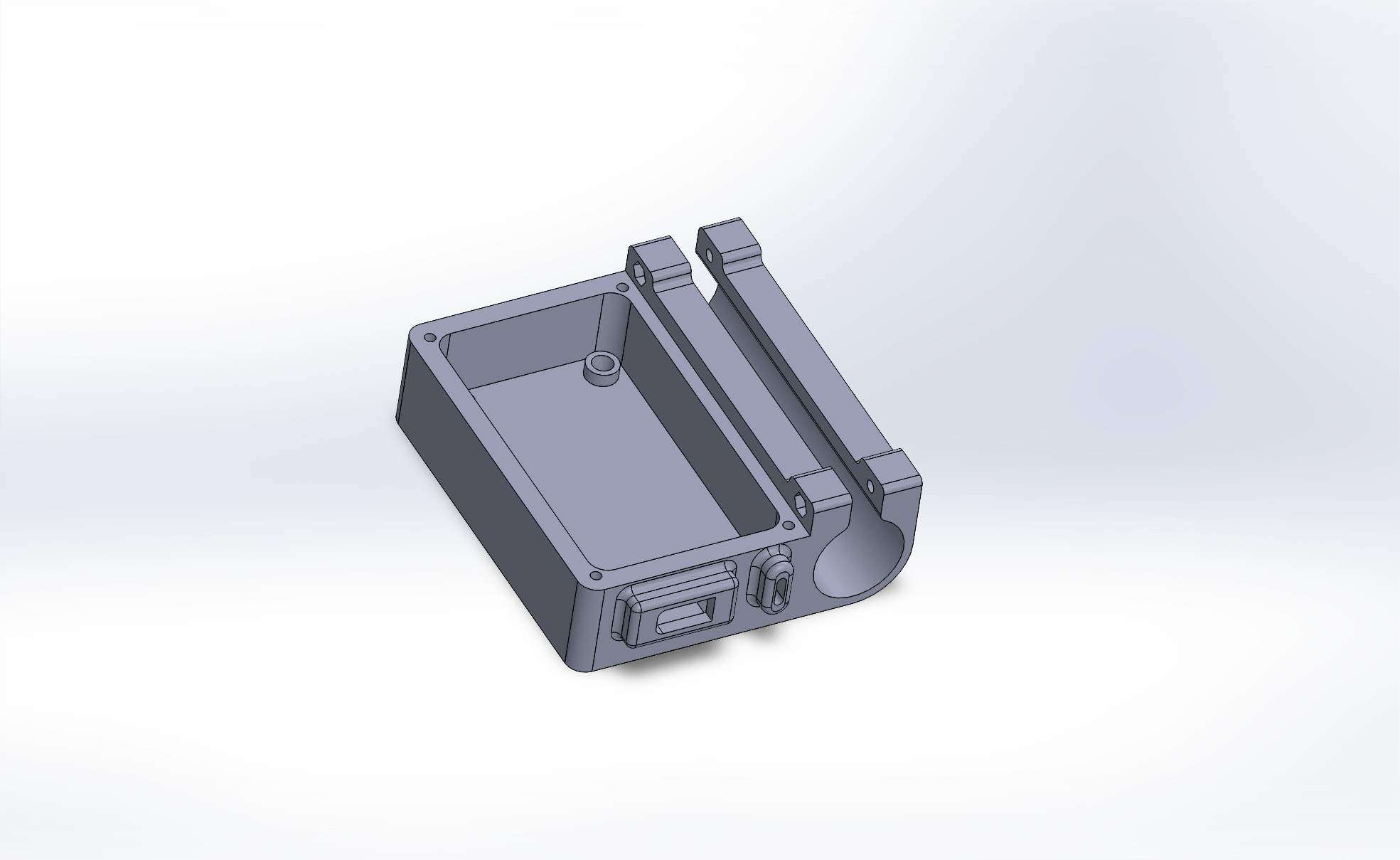

Custom PCB Enclosures

Skills devleoped: Systmem integration, Solidworks, team collaboration, mechanical design. Our car operates on very rough terrain, and uses a number of custom PCBs, both for data acquisition and managing on-car systems. As such, they need enclosures to make sure they are rigidly mounted, waterproof, and accesible in case they need to be repaired. The enclosure on the right was designed for our servo controller, which is the board that controls the actuation mechanism for four wheel drive on our 2023 car. I've also designed the enclosures for the IMU and valve control units (which control our semi active suspension). Because these enclosures are 3D printed, we can abuse their flexibility, and as such, clip onto structural members.

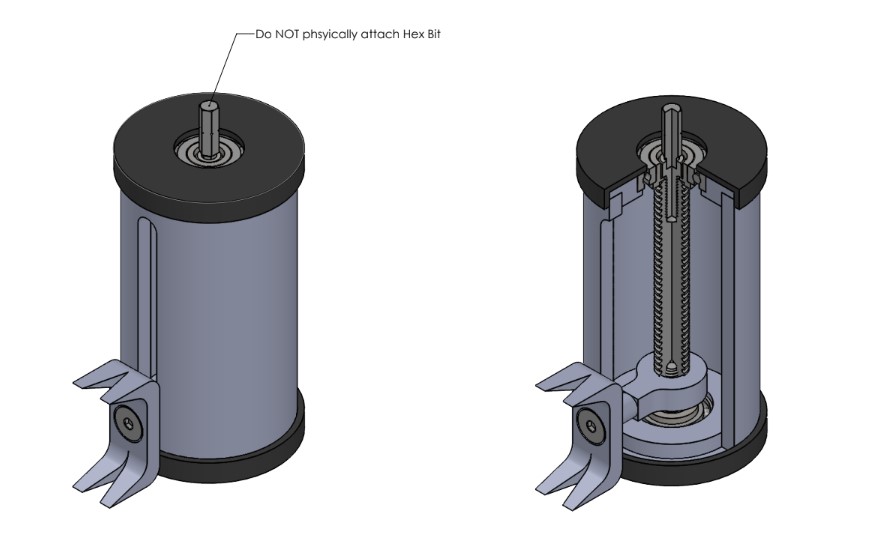

Drill Attachment Nail Remover

Skills developed: Solidworks, team collaboration, making technical drawings, and understanding the limitations of manufacturing procedures like injection molding, machining, and casting. As the name implies, this device is made to remove nails by using the existing power of a drill. The way it works is quite simple: when you rotate the hex end, the puller is constrained in such a way that it moves upwards. The main feature of this design is its symmetry, because if you have multiple nails to remove, you can simply rotate the entire assembly 180 degrees, without the need to power the drill to push puller back to the bottom. The image on the right is the conceptual prototype, while the header image at the top of the page is the proposed final design.

Workbench Hammer

Skills devleoped: Maching on the mill and lathe, reading technical drawings, thread tapping, reaming, grinding, go-nogo check. This hammer was made from low carbon steel, and was the lab project in my design and manufacturing class. We started with square and circular stock, which we then cut to size and machined. After each step, we would check part tolerances using micrometers and calipers( hiting tolerances between +/- 2 thou). As you might expect, none of the tolerances on the hammer were critical (except for the hole sizes), so this was purley for experience.